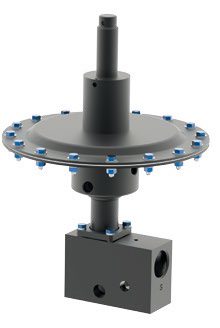

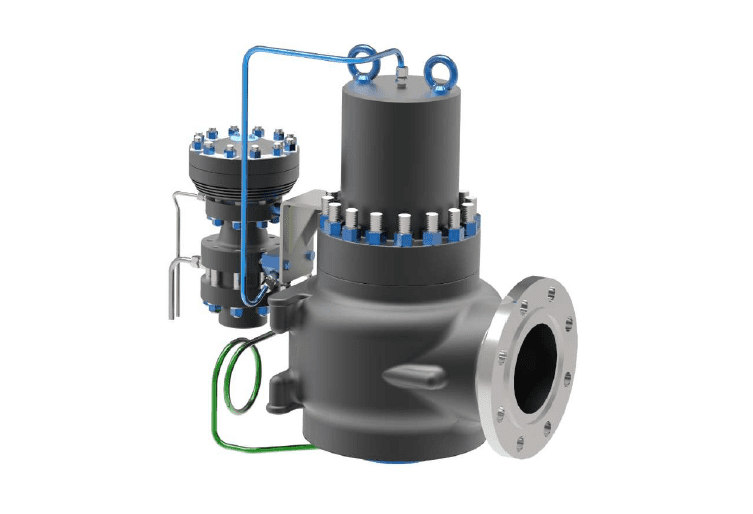

Safety & Pressure Relief Valves (PRV)

Browse a variety of high-performance Safety and Pressure Relief Valves for industrial applications.

Pressure relief valves (PRVs) serve to protect life and property. PRV’s are installed wherever the Maximum Allowable Working Pressure (MAWP) of a process system or pressure vessel could potentially be exceeded.

Failure of a PRV to perform as designed, can result in over pressure of vessels , heat exchangers, boilers or other equipment they were specified and installed to protect. This can result in catastrophic failure and life threatening situations.

- Oil

- Gas; LNG, LPG,

- Fuel Storage

- Vacuum

- Compressed Air

- Liquid

- Chemical

Please contact us to provide a product solution where we can deliver to your site of choice. Users can enquire online for shipping across Australia.

Safety and Pressure Relief Valves explained

Pressure relief valves, Safety valves, Safety relief valves and pressure Safety valves are devices that are designed to protect a process and equipment from excessive pressure build up from fluid or gas.

The valve will automatically discharge a quantity of gas or fluid at a designed safe pressure limit and in most cases re-close to prevent additional fluid or gas being discharged after normal process conditions have been maintained.

What is the difference between a Pressure Relief Valve and Pressure Safety valve?

There are several notable differences between terminology used in both Europe and the US. One of the most important differences is a valve that is referred to as a Safety valve in Europe is referred to as a Pressure Relief Valve in the US. The term Safety valve in the US generally refers specifically to a full-lift type Safety valve used in Europe.

Safety valve sizing and selection

There are a number of elements that go into valve material / type selection to ensure that the desired performance level is achieved against the processes they are designed to protect. Introduce the key factors to consider when sizing and selecting a Safety valve.

Valve material and size

The principal pressure containing components for Safety relief valves are traditionally constructed from and utilised generally in the following applications:

- Bronze – Steam / air / hot water

- Ductile /SG iron – Replaces cast iron for higher pressure valves up to 25bar g.

- Cast Iron – Extensively used in ASME type valves and typically limited to 17bar g.

- Cast Steel – Commonly utilised for higher pressure valves up to 40bar g.

- Austenitic Stainless Steel – food / pharma or clean steam applications

Valve internals and temperature ranges determine the materials to be used such as:

- Viton – High temp gas

- Nitrile – Air and oil applications

- EPDM – water

- Stainless Steel – Standard material for steam applications

- Stellite – Wear resistant applications

During engineering design and through the process of not only materials, process conditions will then determine the correct valve size to be ‘fit for purpose’.

Valve selection process

The important selection process criteria for Safety and Process Relief Valves are:

- Temperature

- Process fluid / gas

- Pressure

- Backpressure

- Capacity for discharge / blow off

- Pipework connection types

With the above process criteria known valve manufacturers / suppliers are able to model with software the range of process conditions to provide expert recommendations. This will provide a product ‘fit for purpose’ that can be engineered to site specifications. From here the valves in operation can be monitored to determine if there are additional fine tuning required due to valve sizing slightly not being correct for application.

Issues that may arise could be valve chatter or flutter. Chatter can occur if the valve inlet sizing restricts flow and the valve closes Valve flutter occurs when the pressure on the discharge side of the valve drops away and the disc moves towards the close position. Then the pressure builds and the valve opens / operates again to discharge.

This places extreme dynamic load on the downstream part of the process and can result in system component damage.

Safety and Pressure Relief Valve services with Multivalve

Safety valve repair

We pride ourselves on having the experience and capability to repair and pressure test industrial valves of all types and brands, both onsite and in our Newcastle facility.

Safety valve testing

Once repairs and servicing work is complete, every valve is pressure tested to the relevant Australian or International Standard.

Frequently asked questions

What pressure should a Safety valve be set to?

The set pressure of a safety or pressure relief device is governed by the material that is being monitored i.e. steam, air and intended to protect the process from immediate danger and injury to persons or equipment. With these known characteristics the use of the relevant standard will determine the set / re-seat pressure.

What are the Safety valve standards in Australia?

Safety and Pressure Relief Valves within Australian industry are set and maintained in accordance with the following standards:

Showing 1–9 of 12 results